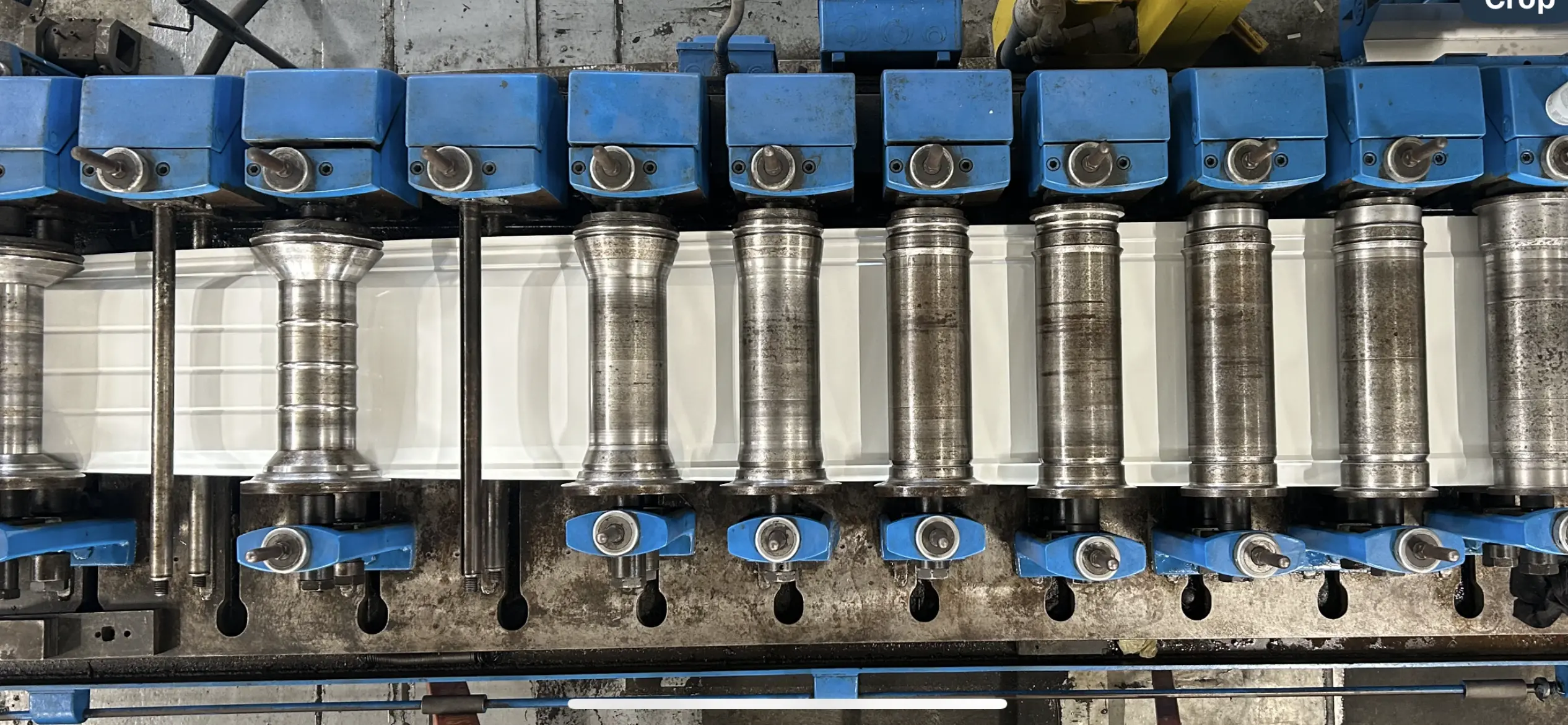

MMC Roll Form is a leader in advanced roll forming technology. Our state-of-the-art facilities boast 14 roll mills and capabilities for handling materials with roll shaft diameters ranging from 1.5" to 3.0". With expertise in 8 to 21 pass sequences, we specialize in producing constant sweep profiles, pre-pierced components, and precise cutoff and notch features. Our offline fabrication and assembly services complement our roll forming, particularly for long-length products and those requiring critical finishes. At MMC, we are dedicated to delivering high-quality, customized metal solutions for diverse industry needs.